Build 2~ vts253a-1993 (medical/lab grade)

The first thing to do, not unlike the vts253b-320 is remove the OEM hose adapter. To do this I use air tools. I don't have a vice, which would be necessary if you use hand tools.

To remove the OEM hose adapter, I used a 9/16" deep impact socket (impact gun), which got me to this point:

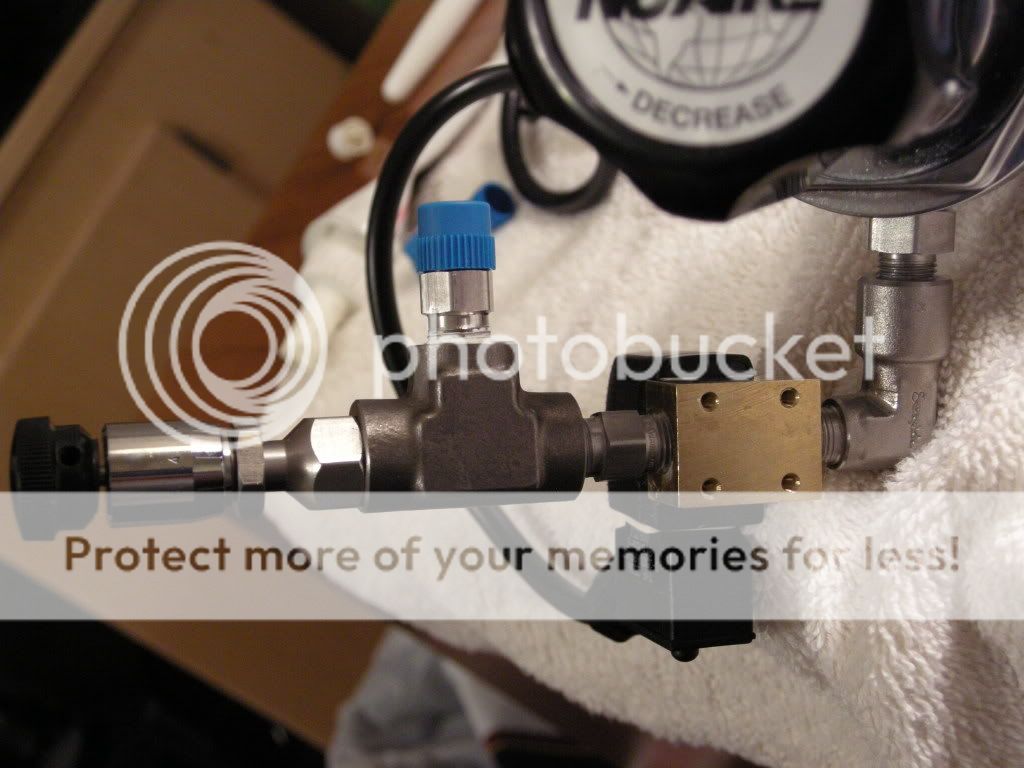

Here is a pic of all the parts (except my chrome plated JBJ bubble counter, which I forgot to get out):

A few things I noticed doing this build:

1) The swagelok stainless steel parts are MUCH better quality than the brass.

2) I can torque th eheck out of the stainless bushings much more than the brass (without worry). The pieces fit together much tighter it seems.

3) The 1993's working adjustment knob seems a bit less accurate and definitely less smooth than the delrin bushing in the vts253b-320. The perceived inaccuracy is maybe due to the fact that the working pressure psi gauge only goes up to 30psi (you can see more movement).

The first thing to do, not unlike the vts253b-320 is remove the OEM hose adapter. To do this I use air tools. I don't have a vice, which would be necessary if you use hand tools.

To remove the OEM hose adapter, I used a 9/16" deep impact socket (impact gun), which got me to this point:

Here is a pic of all the parts (except my chrome plated JBJ bubble counter, which I forgot to get out):

A few things I noticed doing this build:

1) The swagelok stainless steel parts are MUCH better quality than the brass.

2) I can torque th eheck out of the stainless bushings much more than the brass (without worry). The pieces fit together much tighter it seems.

3) The 1993's working adjustment knob seems a bit less accurate and definitely less smooth than the delrin bushing in the vts253b-320. The perceived inaccuracy is maybe due to the fact that the working pressure psi gauge only goes up to 30psi (you can see more movement).

Last edited by a moderator: