300 gallon filter / pump room feedback wanted

- Thread starter rbarn

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

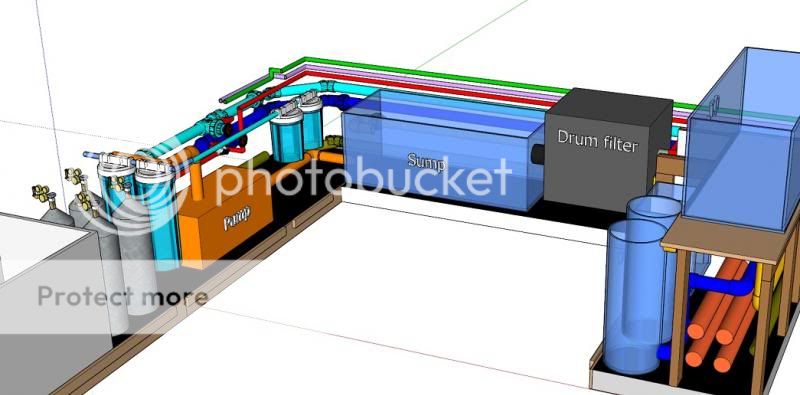

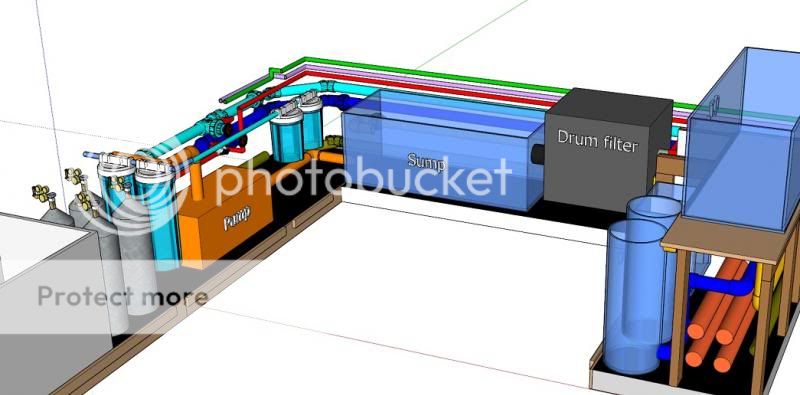

So the drum filter has had me reevaluating my plan.........

1st: ditching the pan world 200 pressure pump and pur-flo cartridge filter

2nd: ditching the pre-filter canisters that were on the bio/Uv/chiller closed loop

3rd: switching to 1 big pump to run everything instead of 3 pumps.

4th: redoing sump plan and incorporating some 5 micron filter socks post drum filter for some super fine water polishing

This will vastly simplify my plumbing layout. I am busy re-planning the pump room now. Stand by for a new sketchup rendering.

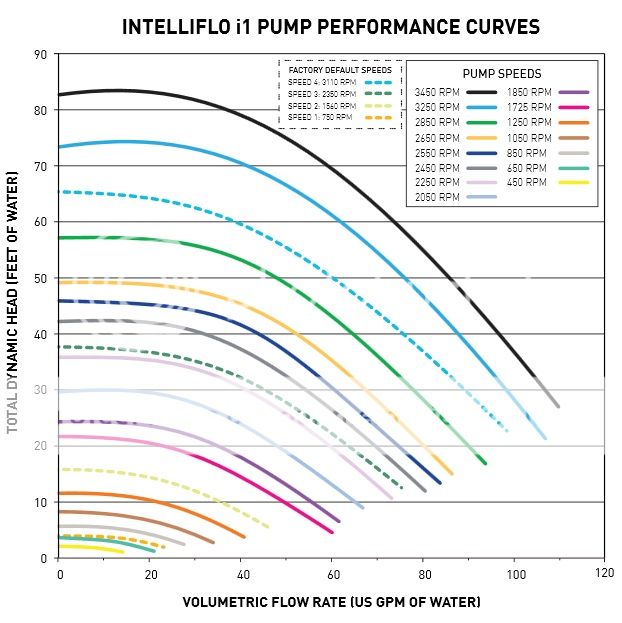

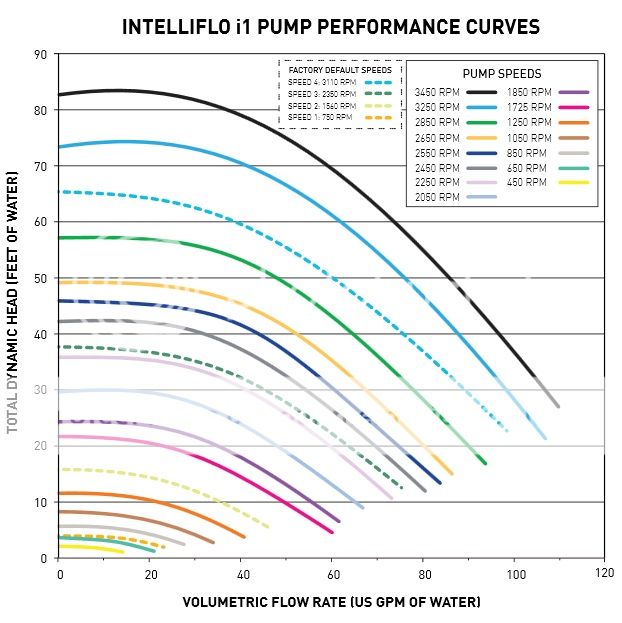

switching back to a single Pentair i1 variable speed DC pool pump - it's on the brown truck now. $930. This is the de-rated 1hp version. I have the 3hp version on my pool and they are incredibly quiet when running at about 2,000 rpm. Very neat pumps, they display their rpm and actual watts being used right on their LCD control screen.

Went by ADG's show room / office last week to see if they had any nice scaping wood to sell. Had tons, but it was all separated out in piles to be used on in-house projects.

1st: ditching the pan world 200 pressure pump and pur-flo cartridge filter

2nd: ditching the pre-filter canisters that were on the bio/Uv/chiller closed loop

3rd: switching to 1 big pump to run everything instead of 3 pumps.

4th: redoing sump plan and incorporating some 5 micron filter socks post drum filter for some super fine water polishing

This will vastly simplify my plumbing layout. I am busy re-planning the pump room now. Stand by for a new sketchup rendering.

switching back to a single Pentair i1 variable speed DC pool pump - it's on the brown truck now. $930. This is the de-rated 1hp version. I have the 3hp version on my pool and they are incredibly quiet when running at about 2,000 rpm. Very neat pumps, they display their rpm and actual watts being used right on their LCD control screen.

Went by ADG's show room / office last week to see if they had any nice scaping wood to sell. Had tons, but it was all separated out in piles to be used on in-house projects.

the sump will maintain proper level in the drum filter and provide for evap and pump start up. It is 48" X 20" X 18" tall.

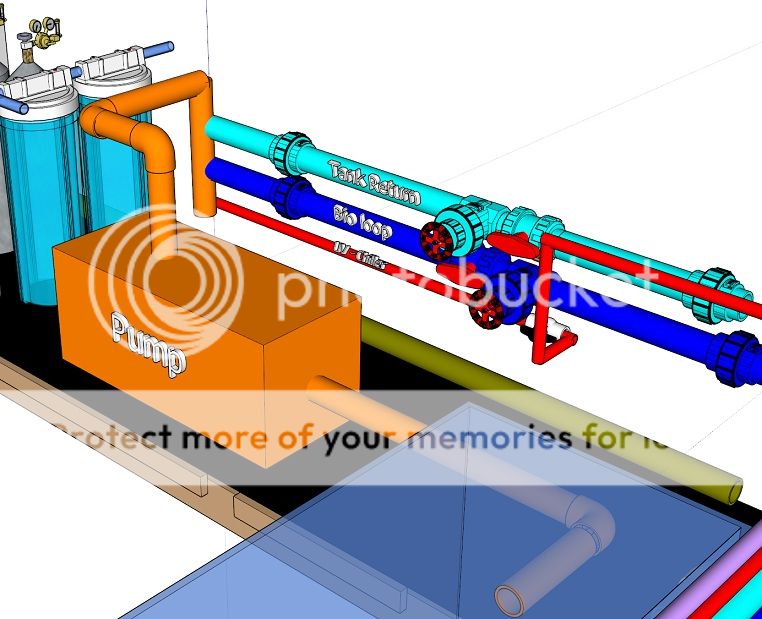

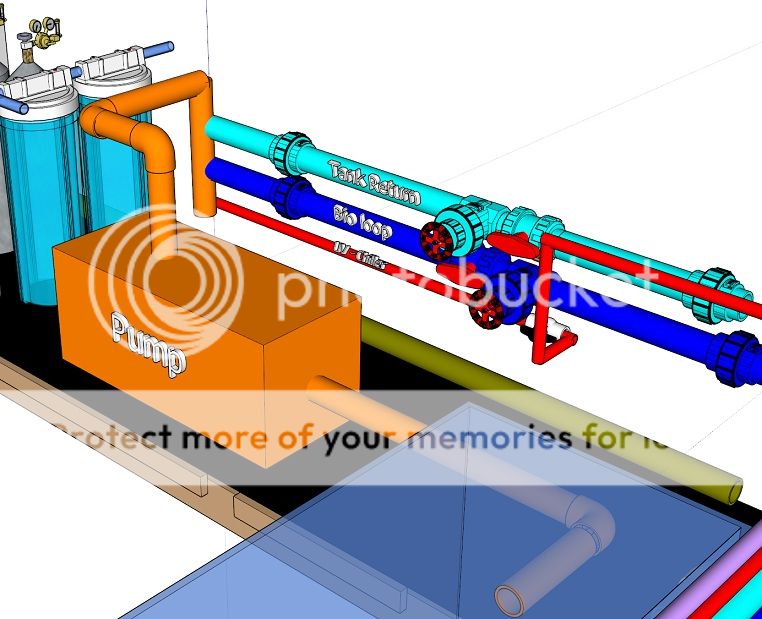

Plumbing is much simpler now. Pump feeds a single manifold that will feed everything else. Each line will have a digital flow meter so I know exactly how much flow each loop will be running.

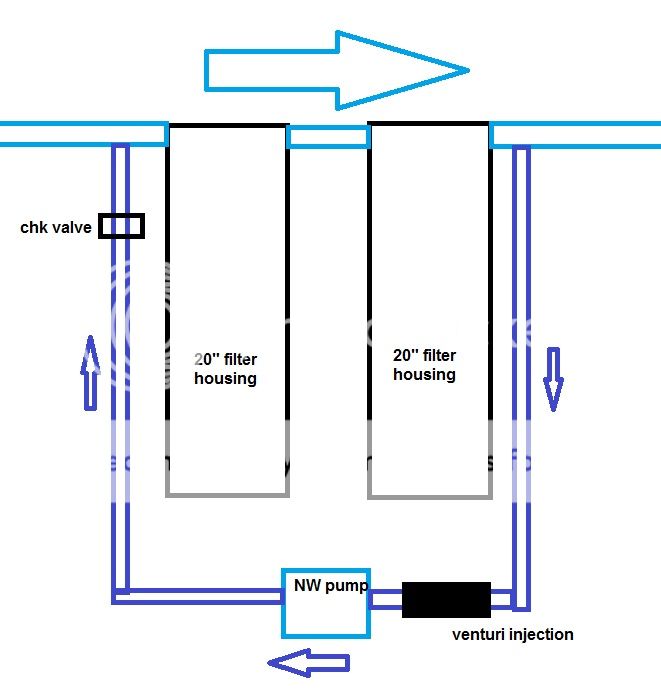

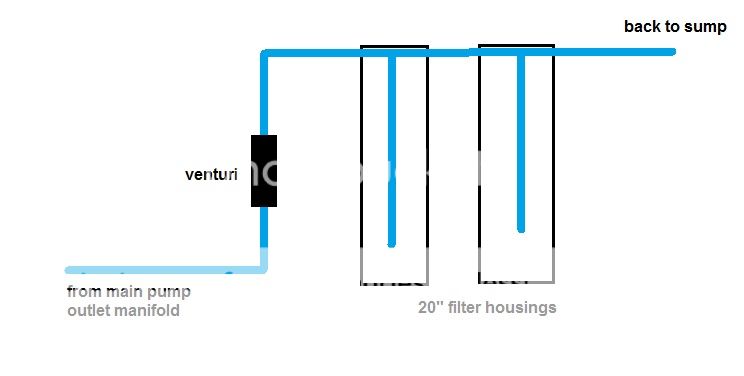

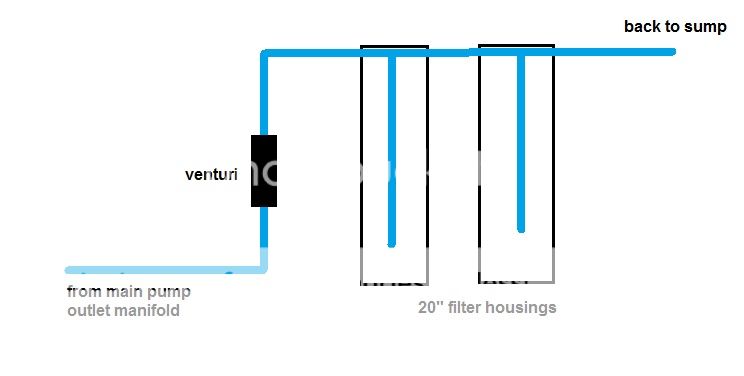

This is my Co2 reaction chamber design I have come up with. The full cross flow will be off the main pump and recirculate back to the sump.

Plumbing is much simpler now. Pump feeds a single manifold that will feed everything else. Each line will have a digital flow meter so I know exactly how much flow each loop will be running.

This is my Co2 reaction chamber design I have come up with. The full cross flow will be off the main pump and recirculate back to the sump.

Last edited by a moderator:

Brown truck dropped this off today.

Been reading the instructions. Very neat pump.

3hp permanent magnet DC motor derated by attaching a 1hp impeller to it.

Infinite speed control from 450 to 3450 rpm

4 preset buttons that can be set at any speed you want

Built in clock/timer pump speed schedule programmer - (it will automatically change pump speeds based on an internal timer)

LCD display shows both pump speed and watts being used

ultra silent and cool running and power efficient

Been reading the instructions. Very neat pump.

3hp permanent magnet DC motor derated by attaching a 1hp impeller to it.

Infinite speed control from 450 to 3450 rpm

4 preset buttons that can be set at any speed you want

Built in clock/timer pump speed schedule programmer - (it will automatically change pump speeds based on an internal timer)

LCD display shows both pump speed and watts being used

ultra silent and cool running and power efficient

Last edited by a moderator:

Better plan simple is always better.

Nothing wrong using all gold standard type stuff, cool items etc.............

I would make sure to have a secondary pump/and/or filter system perhaps.

CO2 should be fine, it's not a needed item to have it all run through the reactors, just enough flow to feed back into the main line and mix well before entering the tank.

So a simpler design would be a bypass with the NW sucking off the main line and then looping back again. No check valve needed there and you'd place the NW on the upstream end.

The NW will pull all that it needs down that path from the main return without head loss. Check valve and all......more trouble that it's worth.

You do not need it.

Make sure you can access the NW pump, that's about the only service area you'll need for that loop.

Nice pump.

2000 rpm ought to do it.

How are your returns? Ideally a pair of 2" PVC sized elbows would be good at opposite ends of the tank.

Nothing wrong using all gold standard type stuff, cool items etc.............

I would make sure to have a secondary pump/and/or filter system perhaps.

CO2 should be fine, it's not a needed item to have it all run through the reactors, just enough flow to feed back into the main line and mix well before entering the tank.

So a simpler design would be a bypass with the NW sucking off the main line and then looping back again. No check valve needed there and you'd place the NW on the upstream end.

The NW will pull all that it needs down that path from the main return without head loss. Check valve and all......more trouble that it's worth.

You do not need it.

Make sure you can access the NW pump, that's about the only service area you'll need for that loop.

Nice pump.

2000 rpm ought to do it.

How are your returns? Ideally a pair of 2" PVC sized elbows would be good at opposite ends of the tank.

Better plan simple is always better.

Nothing wrong using all gold standard type stuff, cool items etc.............

I would make sure to have a secondary pump/and/or filter system perhaps.

CO2 should be fine, it's not a needed item to have it all run through the reactors, just enough flow to feed back into the main line and mix well before entering the tank.

So a simpler design would be a bypass with the NW sucking off the main line and then looping back again. No check valve needed there and you'd place the NW on the upstream end.

The NW will pull all that it needs down that path from the main return without head loss. Check valve and all......more trouble that it's worth.

You do not need it.

Make sure you can access the NW pump, that's about the only service area you'll need for that loop.

Nice pump.

2000 rpm ought to do it.

How are your returns? Ideally a pair of 2" PVC sized elbows would be good at opposite ends of the tank.

Nothing wrong using all gold standard type stuff, cool items etc.............

I would make sure to have a secondary pump/and/or filter system perhaps.

CO2 should be fine, it's not a needed item to have it all run through the reactors, just enough flow to feed back into the main line and mix well before entering the tank.

So a simpler design would be a bypass with the NW sucking off the main line and then looping back again. No check valve needed there and you'd place the NW on the upstream end.

The NW will pull all that it needs down that path from the main return without head loss. Check valve and all......more trouble that it's worth.

You do not need it.

Make sure you can access the NW pump, that's about the only service area you'll need for that loop.

Nice pump.

2000 rpm ought to do it.

How are your returns? Ideally a pair of 2" PVC sized elbows would be good at opposite ends of the tank.

Tom Barr;119505 said:How are your returns? Ideally a pair of 2" PVC sized elbows would be good at opposite ends of the tank.

Thats the next thing I have been thinking about. I was thinking some large clear PVC elbows in the front corners, or maybe go with Line-Loc and do a bunch of them around the perimeter with little iso-valves to control flow on each one, or maybe even run some pipe down to the bottom of the tank and have it up flowing out of a mass of wood like a natural spring would in nature or some combination of all three with valves on everything

Tom Barr;119504 said:I would make sure to have a secondary pump/and/or filter system perhaps.

I do eventually plan on ordering another identical pump to have sitting here in case of failure and flow switch on the return that will tell the Apex if water stops moving through the pipes.

http://www.aquaticeco.com/subcategories/1214/In-Line-Flow-Switches

Last edited by a moderator:

Been doing some more research on this pump. I will be able to control it with the Apex controller.

Pentair makes a $160 interface box that will let me switch between any of the 4 preset speeds I program into the pump by sending a 10v signal from the Apex's LED dimming control module to the interface box.

I won't be ale to adjust speed from the Apex but being able to change to preset speeds through the controller should be handy

Pentair makes a $160 interface box that will let me switch between any of the 4 preset speeds I program into the pump by sending a 10v signal from the Apex's LED dimming control module to the interface box.

I won't be ale to adjust speed from the Apex but being able to change to preset speeds through the controller should be handy

Loc line are too narrow and produce very high pressure.

Clean PVC ends up covered with algae like ADA lily pipes.

Best to use black or match the color with the back of the tank.

I'd run say 1" lines to each 2" PVC elbow, this will reduce the pressure while not lowering the flow rate.

High flow, but low pressure, a Vortech MP40 would work for any need current, you have a great deal of filter which just is not needed to this level for a planted tank.

Nice to have..........but good current and lower flow through the filter would work better.

You want currents to be not more than 1 mph basically and the output of the loc lines are all ranging fast.

Clean PVC ends up covered with algae like ADA lily pipes.

Best to use black or match the color with the back of the tank.

I'd run say 1" lines to each 2" PVC elbow, this will reduce the pressure while not lowering the flow rate.

High flow, but low pressure, a Vortech MP40 would work for any need current, you have a great deal of filter which just is not needed to this level for a planted tank.

Nice to have..........but good current and lower flow through the filter would work better.

You want currents to be not more than 1 mph basically and the output of the loc lines are all ranging fast.

Thanks Tom, Good info

I'll do some 1.5" outlets in the upper corners with a combination of some adjustable spray bars along the perimeter.

Got Mazzei venturi injector in today. Very nice piece, made for ozone injection so the plastic is super thick and resistant to break down. Should last forever with Co2.

Not cheap at $70 for the 3/4 version rated for 7gpm, but claims 90% diffusion rate. Has built in check valve too.

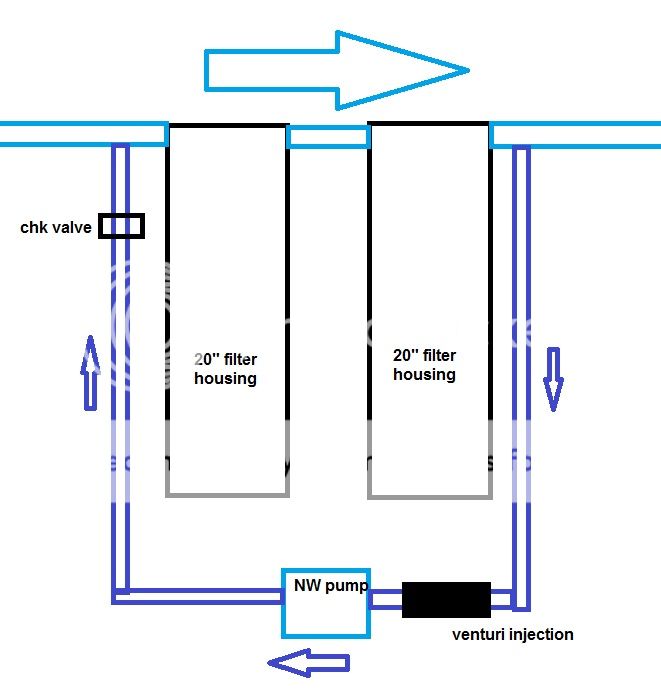

New simpler co2 reactor plan using the venturi. No secondary NW pump.

I'll do some 1.5" outlets in the upper corners with a combination of some adjustable spray bars along the perimeter.

Got Mazzei venturi injector in today. Very nice piece, made for ozone injection so the plastic is super thick and resistant to break down. Should last forever with Co2.

Not cheap at $70 for the 3/4 version rated for 7gpm, but claims 90% diffusion rate. Has built in check valve too.

New simpler co2 reactor plan using the venturi. No secondary NW pump.

I moved away from Venturis due to the head pressure loss. At long as the incoming flow is stable, you are okay.

They do atomize gas better than most anything, well, downdrafts do an awesome job and NW.

For in line apps, they do well.

For lower pressure in sump systems, a reactor with a NW does the job better and used the pump's energy much much more efficiently.

The loop you have will do well. But the same could be done with a 400-600 gph pump and NW.

I would run about 500-600 gph from the pump manifold.

See how much mist you get back into the sump and place this upstream in the sump area, this will reduce the amount of mist that ends up inside the main tank.

CO2 mist really has a larger impact on larger tanks than smaller ones.

So getting it out before the return pump is key.

Venturis make such a fine mist, they might stay in solution longer than say the less efficient NW or bubbling it into the reactors with air line counter current etc.

They do atomize gas better than most anything, well, downdrafts do an awesome job and NW.

For in line apps, they do well.

For lower pressure in sump systems, a reactor with a NW does the job better and used the pump's energy much much more efficiently.

The loop you have will do well. But the same could be done with a 400-600 gph pump and NW.

I would run about 500-600 gph from the pump manifold.

See how much mist you get back into the sump and place this upstream in the sump area, this will reduce the amount of mist that ends up inside the main tank.

CO2 mist really has a larger impact on larger tanks than smaller ones.

So getting it out before the return pump is key.

Venturis make such a fine mist, they might stay in solution longer than say the less efficient NW or bubbling it into the reactors with air line counter current etc.

I moved away from Venturis due to the head pressure loss. At long as the incoming flow is stable, you are okay.

They do atomize gas better than most anything, well, downdrafts do an awesome job and NW.

For in line apps, they do well.

For lower pressure in sump systems, a reactor with a NW does the job better and used the pump's energy much much more efficiently.

The loop you have will do well. But the same could be done with a 400-600 gph pump and NW.

I would run about 500-600 gph from the pump manifold.

See how much mist you get back into the sump and place this upstream in the sump area, this will reduce the amount of mist that ends up inside the main tank.

CO2 mist really has a larger impact on larger tanks than smaller ones.

So getting it out before the return pump is key.

Venturis make such a fine mist, they might stay in solution longer than say the less efficient NW or bubbling it into the reactors with air line counter current etc.

They do atomize gas better than most anything, well, downdrafts do an awesome job and NW.

For in line apps, they do well.

For lower pressure in sump systems, a reactor with a NW does the job better and used the pump's energy much much more efficiently.

The loop you have will do well. But the same could be done with a 400-600 gph pump and NW.

I would run about 500-600 gph from the pump manifold.

See how much mist you get back into the sump and place this upstream in the sump area, this will reduce the amount of mist that ends up inside the main tank.

CO2 mist really has a larger impact on larger tanks than smaller ones.

So getting it out before the return pump is key.

Venturis make such a fine mist, they might stay in solution longer than say the less efficient NW or bubbling it into the reactors with air line counter current etc.

I've been thinking about the mist some too.

I was thinking I would fill the filter housings with simple plastic dish scrubber pads or something similar to try and catch or slow down the micro bubbles, and maybe even having the return come back into the sump in an isolated chamber that forces the water through a 1-2" block of 10ppi filter foam to trap the bubble there.

I really do want that "water so clear it looks they're floating in empty space" look when its all said and done.

I was thinking I would fill the filter housings with simple plastic dish scrubber pads or something similar to try and catch or slow down the micro bubbles, and maybe even having the return come back into the sump in an isolated chamber that forces the water through a 1-2" block of 10ppi filter foam to trap the bubble there.

I really do want that "water so clear it looks they're floating in empty space" look when its all said and done.

Venturi mist, even most of the NW mist are too small for the bioballs/mesh etc to catch them, they act like water more than bubbles at those sizes.

You gain more surface to volume ratio, but you lose the efficacy of the counter current Columns which are in place to catch the gas.

It's a trade off.

You gain more surface to volume ratio, but you lose the efficacy of the counter current Columns which are in place to catch the gas.

It's a trade off.

Venturi mist, even most of the NW mist are too small for the bioballs/mesh etc to catch them, they act like water more than bubbles at those sizes.

You gain more surface to volume ratio, but you lose the efficacy of the counter current Columns which are in place to catch the gas.

It's a trade off.

You gain more surface to volume ratio, but you lose the efficacy of the counter current Columns which are in place to catch the gas.

It's a trade off.